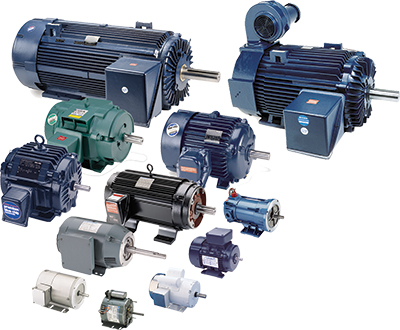

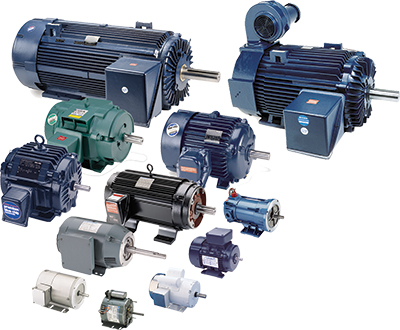

Seven common NEMA motor types

In homogenizing manufacturing consistency, the National Electrical Manufacturers Association (NEMA) created a set of standards describing the various sizes of electric motors. NEMA frames are organized into groups where all mounting dimensions are identical.

The reason for this system allows for substitution of a motor manufactured by one company with a different company, if the frame isn’t unique.

The reason for this system allows for substitution of a motor manufactured by one company with a different company, if the frame isn’t unique.

In an excellent article at the Electrical Engineering Portal, Edvard points out the seven common NEMA motor types:

The reason for this system allows for substitution of a motor manufactured by one company with a different company, if the frame isn’t unique.

The reason for this system allows for substitution of a motor manufactured by one company with a different company, if the frame isn’t unique.In an excellent article at the Electrical Engineering Portal, Edvard points out the seven common NEMA motor types:

1. Open Drip Proof (ODP)

Allows air to circulate through the windings for cooling, but prevent drops of liquid from falling into motor within a 15 degree angle from vertical. Typically used for indoor applications in relatively clean, dry locations.

2. Totally Enclosed Fan Cooled (TEFC)

Prevents the free exchange of air between the inside and outside of the frame, but does not make the frame completely air tight. A fan is attached to the shaft and pushes air over the frame during its operation to help in the cooling process.

The ribbed frame is designed to increase the surface area for cooling purposes.

The TEFC style enclosure is the most versatile of all. It is used on pumps, fans, compressors, general industrial belt drive and direct connected equipment.

3. Totally Enclosed Non-Ventilated (TENV)

Similar to a TEFC, but has no cooling fan and relies on convention for cooling. No vent openings, tightly enclosed to prevent the free exchange of air, but not airtight.

These are suitable for uses which are exposed to dirt or dampness, but not very moist or hazardous (explosive) locations.

4. Totally Enclosed Air Over (TEAO)

Dust-tight fan and blower duty motors designed for shaft mounted fans or belt driven fans. The motor must be mounted within the airflow of the fan.

5. Totally Enclosed Wash down (TEWD)

Designed to withstand high pressure wash-downs or other high humidity or wet environments. Available on TEAO, TEFC, and ENV enclosures totally enclosed, hostile and severe environment motors:

Designed for use in extremely moist or chemical environments, but not for hazardous locations.

6. Explosion-proof enclosures (EXPL)

The explosion proof motor is a totally enclosed machine and is designed to withstand an explosion of specified gas or vapor inside the motor casing and prevent the ignition outside the motor by sparks, flashing or explosion.

These motors are designed for specific hazardous purposes, such as atmospheres containing gases or hazardous dusts. For safe operation, the maximum motor operating temperature must be below the ignition temperature of surrounding gases or vapors.

Explosion proof motors are designed, manufactured and tested under the rigid requirements of the Underwriters Laboratories.

7. Hazardous Location (HAZ)

Hazardous location motor applications are classified by the type of hazardous environment present, the characteristics of the specific material creating the hazard, the probability of exposure to the environment, and the maximum temperature level that is considered safe for the substance creating the hazard.

The format used to define this information is a class, group, division and temperature code structure as defined by the National Electric Code (NFPA-70).

<- - Make a Comment - ->

Servo Motor & Drives

Servo Motor & Drives